Description

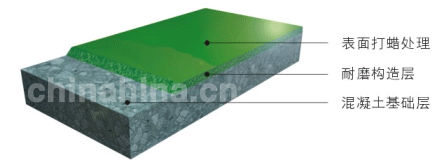

Floor-hardened wear-resistant material is an instant available wear-resistant ground material mixed with special orthopedic (mineral orthopedics, metal orthopedics) polymers and additives.

In the initial setting stage of ordinary concrete pouring, the flat hardening wear resistance materials evenly spread on the concrete surface, by professional mechanical equipment in accordance with the standard procedures, so as to form a whole with the concrete base, and has high density, and colored high performance hardening wear resistance ground, local floor hardening wear resistance materials used in industrial plant ground, can double the wear resistance and impact of the ground.

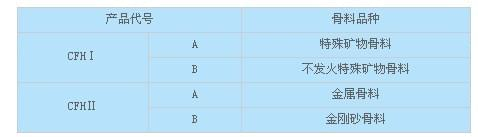

Product code name and category

Floor hardening wear-resistant materials are divided into four floor types according to different orthopedic varieties.

Scope of product use

Industrial plants require higher wear resistance and impact resistance

Industrial plants need to withstand greater loads and frequent traffic areas.

Public facilities and commercial land, supermarkets, parking lots, schools, squares, municipal roads.

Factory warehouse land, automobile service center, platform, cold storage and wear-resistant transportation floor.

Need to improve the work health environment and sigh floor.

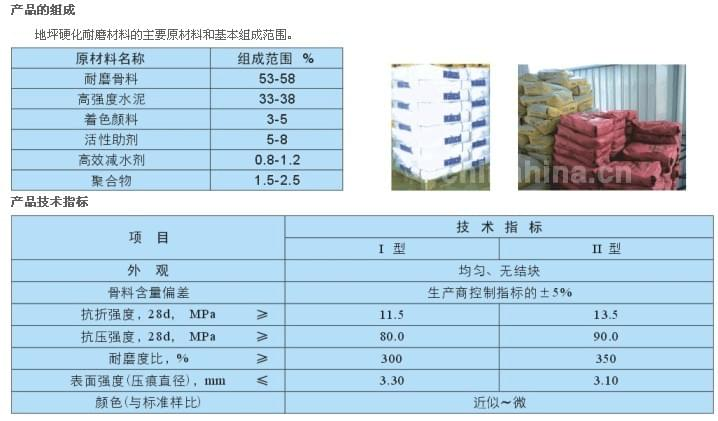

product mix

product features

Wear-resistant floor construction does not have additional construction period.

Increase the wear resistance and strength of concrete ground more than 3 times.

The overall color avoids the cost of periodic coating or surface thickening of other materials.

Reduce freight tool wheel wear to the ground.

The high density of the ground floor increases the ground permeability resistance to oil, hydraulic oil and chemical reagents.

Less absorption of water and cleaners, excellent surface density makes the floor clean, easy to repair, and more expensive.

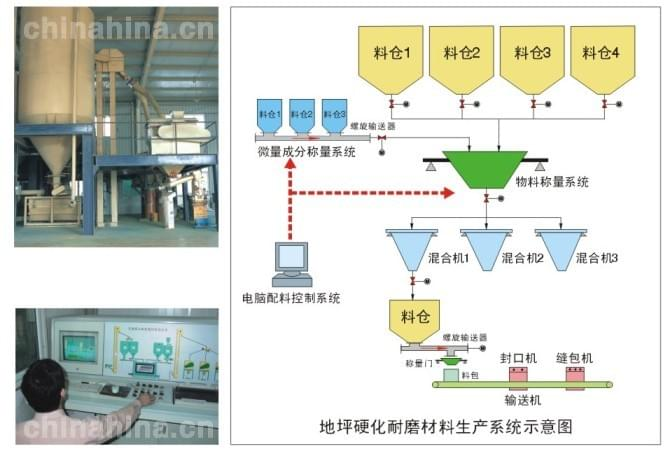

Introduction to production process

Floor hardened wear-resistant materials are composed of computer batching system and multi-stage mixing system to ensure the uniformity of materials and the effective incorporation of trace added ingredients. The production process is carried out in strict accordance with ISO9001:2001 quality management system procedure documents to ensure the quality of products.

Product identification and engineering examples

Floor-hardened wear-resistant material is a new material product jointly developed by Ningbo Rongshan New Material Co., Ltd. and Zhejiang University. Since 1996, it has been used for nearly 10 million square meters in China, and has achieved obvious social and economic benefits.

"Research and industrial development of super wear-resistant color ground hardened materials" passed the expert appraisal organized by Zhejiang Provincial Science and Technology Department in November 2003. The technical level of the product is leading in China, and some technical indicators reach the advanced level of similar foreign products.

Wear-resistant diamond sand floor floor

Wear-resistant diamond floor is an instant available wear-resistant ground material mixed with special orthopedic (mineral orthopedics, metal orthopedics) polymers and additives. In the initial setting stage of ordinary concrete pouring, the flat hardening wear resistance materials evenly spread on the concrete surface, by professional mechanical equipment in accordance with the standard procedures, so as to form a whole with the concrete base, and has high density, and colored high performance hardening wear resistance ground, local floor hardening wear resistance materials used in industrial plant ground, can double the wear resistance and impact of the ground. Product code and category Floor hardened wear-resistant materials are divided into four floor types according to different orthopedic varieties.

Product use scope industrial plants need higher requirements of wear resistance and impact of the surface industrial plants need to withstand greater loads and frequent traffic areas. Public facilities and commercial land, supermarkets, parking lots, schools, squares, municipal roads. Factory warehouse land, automobile service center, platform, cold storage and wear-resistant transportation floor. Need to improve the work health environment and sigh floor.product mix

Product characteristics wear-resistant floor construction does not add additional construction period. Increase the wear resistance and strength of concrete ground more than 3 times. The overall color avoids the cost of periodic coating or surface thickening of other materials. Reduce freight tool wheel wear to the ground. The high density of the ground floor increases the ground permeability resistance to oil, hydraulic oil and chemical reagents. Less absorption of water and cleaners, excellent surface density makes the floor clean, easy to maintain, and more expensive. The floor hardened wear-resistant materials are composed of computer mixing system and multi-stage mixing system to ensure the uniformity of the material and the effective incorporation of trace added ingredients. The production process is strictly in accordance with ISO9001:2001 quality management system procedure documents to ensure the quality of products.

Floor floor hardened wear-resistant material is a new material product jointly developed by Ningbo Rongshan New Material Co., Ltd. and Zhejiang University. Since 1996, it has been nearly 10 million square meters of engineering use cases in China, and has achieved obvious social and economic benefits."Research and industrial development of super wear-resistant color ground hardened materials" passed the expert appraisal organized by Zhejiang Provincial Science and Technology Department in November 2003. The technical level of the product is leading in China, and some technical indicators reach the advanced level of similar foreign products.